Glass bead blasting is a surface treatment process that involves the use of small glass beads propelled by compressed air to clean, finish, or prepare surfaces. This method is commonly used in various industries for its effectiveness and efficiency in providing a smooth, polished finish.

How to glass bead blast?

Preparation: The surface to be treated is cleaned to remove any loose debris or contaminants.

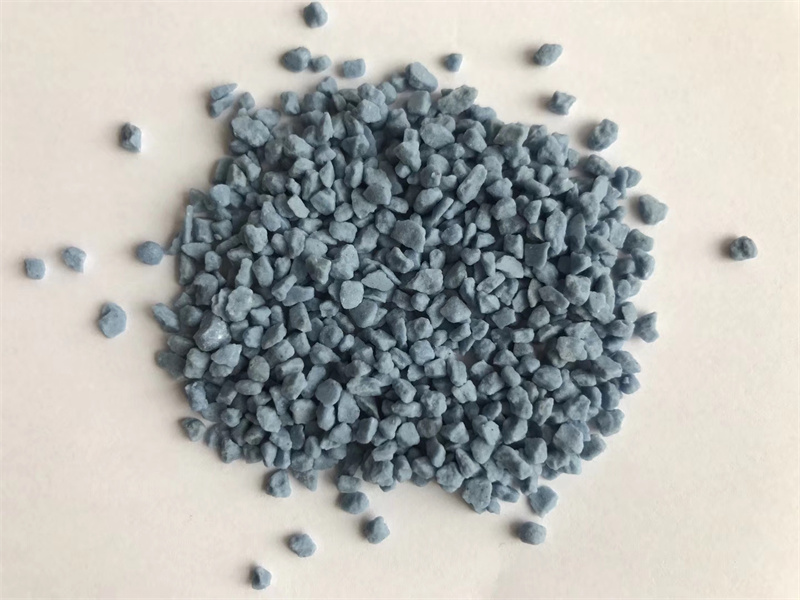

Blasting: Glass beads, typically made from lead-free, soda-lime-type glass, are blasted at high velocity onto the surface using compressed air.

Impact: The beads strike the surface and cause a peening action, which not only cleans but also strengthens the material by creating compressive stress on its surface.

Finishing: The surface is then inspected and may undergo further treatments if necessary.

Applications of glass bead blast

Cleaning: Removing rust, paint, scale, and other contaminants from surfaces without causing significant damage to the underlying material.

Finishing: Providing a uniform surface finish that can range from a matte to a satin finish, depending on the size of the beads and the pressure used.

Surface Preparation: Preparing surfaces for subsequent coating or painting by creating a texture that improves the adhesion of the new layer.

Peening: Enhancing the mechanical properties of the material by inducing compressive stresses, which can improve fatigue resistance.

Advantages of glass bead blasting

Non-Damaging: Unlike other abrasive methods, glass bead blasting is gentle and doesn’t remove significant amounts of material, preserving the integrity of the surface.

Eco-Friendly: Glass beads are non-toxic and can be recycled multiple times before they break down, making the process more environmentally friendly.

Versatile: Suitable for a wide range of materials including metals, plastics, and glass, making it applicable in industries like automotive, aerospace, and manufacturing.

Improves Appearance: Provides a clean, uniform, and aesthetically pleasing finish, which is important for components that will be visible.