Sandblasting, also known as abrasive blasting, uses various grades of sand or other abrasive materials to clean or etch surfaces. The grade of the sand affects the surface finish, cutting speed, and the type of material that can be effectively blasted.

Sandblasting Sand Grades

Extra Coarse (12-20 mesh)

Mesh Size: 12-20

Microns: 1680 - 841 µm

Application: Heavy-duty applications such as removing thick paint, rust, or heavy mill scale. Suitable for large surfaces and heavy machinery.

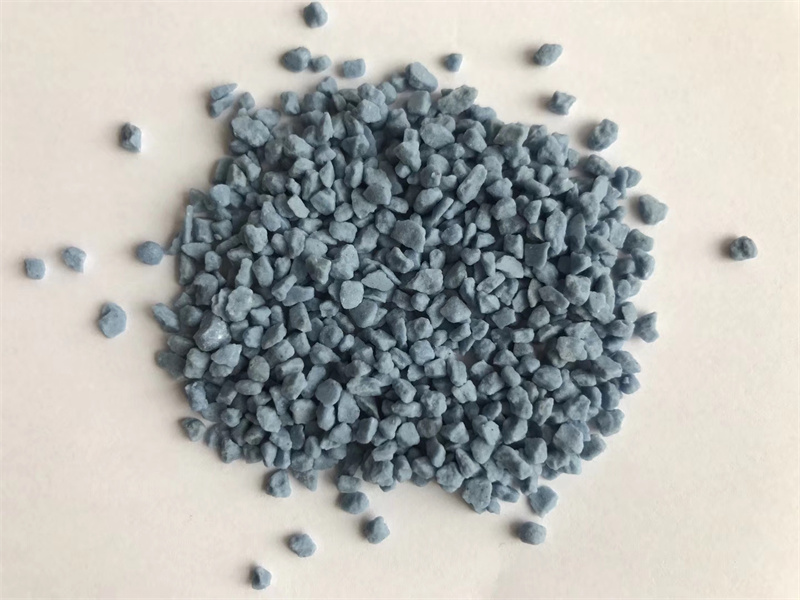

Coarse (20-40 mesh)

Mesh Size: 20-40

Microns: 841 - 420 µm

Application: General-purpose blasting for paint and rust removal. Commonly used for surface preparation before coating or painting.

Medium (40-60 mesh)

Mesh Size: 40-60

Microns: 420 - 250 µm

Application: Suitable for surface preparation and cleaning, removing paint or rust from smaller objects, and achieving a moderate surface profile.

Fine (60-80 mesh)

Mesh Size: 60-80

Microns: 250 - 177 µm

Application: Provides a finer surface finish, used for lighter cleaning tasks and creating a smooth surface profile for delicate substrates.

Extra Fine (80-120 mesh)

Mesh Size: 80-120

Microns: 177 - 125 µm

Application: Used for precise and detailed work, such as cleaning softer metals, preparing surfaces for intricate coatings, or polishing.

Micro-Fine (120-200 mesh)

Mesh Size: 120-200

Microns: 125 - 74 µm

Application: Extremely fine blasting, ideal for very delicate surfaces, polishing, and achieving a very smooth finish.

About the Grades

Mesh Size: Represents the number of openings per inch in a screen through which the sand particles pass. A higher mesh number indicates finer particles.

Microns: Provides a precise measurement of particle size in micrometers.