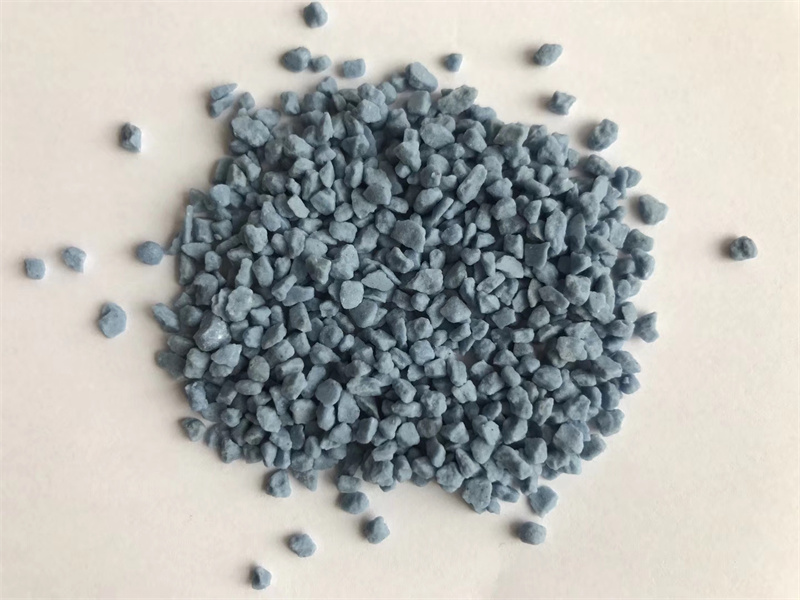

Glass beads are used in a variety of applications, including abrasive blasting, shot peening, and as reflective elements in road markings. The size of glass beads is typically measured in microns (µm) or based on a mesh size, which refers to the number of openings per inch in a screen through which the beads can pass. Here’s a general size chart for glass beads:

Glass Beads Size Chart

| Mesh Size | Microns (µm) | Inches |

|---|---|---|

| 10 - 20 | 2000 - 850 | 0.0787 - 0.0335 |

| 20 - 30 | 850 - 600 | 0.0335 - 0.0236 |

| 30 - 40 | 600 - 425 | 0.0236 - 0.0167 |

| 40 - 50 | 425 - 300 | 0.0167 - 0.0118 |

| 50 - 70 | 300 - 212 | 0.0118 - 0.0083 |

| 70 - 100 | 212 - 150 | 0.0083 - 0.0059 |

| 100 - 120 | 150 - 125 | 0.0059 - 0.0049 |

| 120 - 200 | 125 - 75 | 0.0049 - 0.0029 |

| 200 - 325 | 75 - 45 | 0.0029 - 0.0017 |

| -325 | < 45 | < 0.0017 |

About the Chart

Mesh Size: Indicates the range of sieve sizes through which the glass beads can pass. For example, beads labeled as 20-30 mesh will pass through a 20-mesh screen but be retained by a 30-mesh screen.

Microns (µm): One micron is one-millionth of a meter. This column provides a more precise size range of the beads in micrometers.

Inches: Conversion of microns to inches for a more intuitive understanding.

Common Applications

Abrasive Blasting: Larger beads (e.g., 20-40 mesh) are used for cleaning and peening operations.

Shot Peening: Specific sizes are chosen based on the desired surface finish and material specifications.

Reflective Road Markings: Smaller beads (e.g., 200 mesh and finer) are used to enhance visibility at night by reflecting light from headlights.

When selecting glass beads for a particular application, it is essential to consider the desired outcome, material compatibility, and equipment specifications. Always refer to industry standards and manufacturer recommendations for optimal results.